Proper maintenance of wires at sea is critical. Hot temperatures cause many greases to drip and sea water often washes off grease, leaving wires exposed. Sea water can penetrate into the wire core, where it causes a lot of damage - in particular: rust.

Wire lubrication is also important. Abrasion and wear internally between wire strands, as well as when the wire runs through sheaves or onto winches, will cause premature wire rope failure if the grease being used is not of a sufficient quality or if there is not enough grease in place.

To ensure wires are in optimal condition, wires need cleaning, internal protection and external protection. This can all be done manually; Ferryl Rustoil Penetrating Oil cleans off old grease and contaminants while removing moisture from the core; Ferryl 101 Anticorrosive Oil provides rust protection and lubrication in the wire core; followed by an application of Ferryl 202 Standard Anticorrosive Grease for external protection.

The Product:

The Ferryl Wire Rope Lubricator

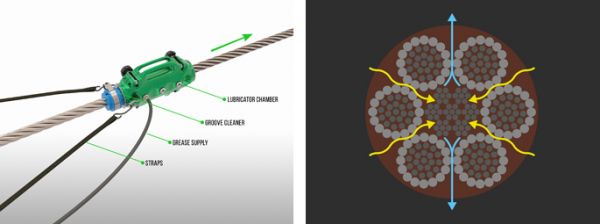

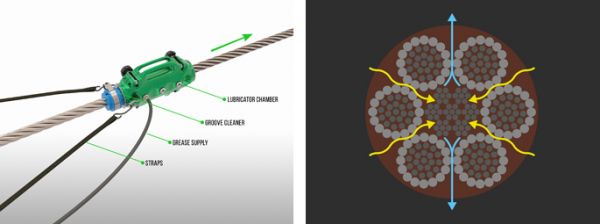

The Ferryl Wire Rope Lubricator is a high-pressure semi-automatic wire rope greasing machine. Grease is pumped at up to 400 bar into the high-pressure lubricating chamber as the wire passes through. The pressure forces the grease into the wire core, forcing out water and moisture. The wire leaves the chamber with a uniform grease coating, inside and out.

Optional groove cleaners can be positioned at the entry point of the chamber to remove old grease and debris.

Application time can be drastically reduced (as compared to manual greasing), as the lubricator can grease wires at a speed of up to 40m per minute. Pre-treatment / cleaning, internal protection and external protection is done in one step, and an even coat of grease is always applied. This means managers can be sure that the proper maintenance gets done on board and no steps are skipped.

Properly maintained wires mean a safer working environment on board, extended wire life and reducing cost.

Additional or Alternative Products

The Ferryl Wire Rope Lubricator is designed for use with Ferryl 202 Standard Anticorrosive Grease, the ultimate wire rope grease for the shipping industry.

Although many different grease pumps can be used with the lubricator, Ferryl have also developed the Ferryl Pump Unit. The pump unit features a high pressure 40:1 high flow grease pump, which together with a pneumatic ram makes pumping the grease as easy as possible. Easily adjustable controls makes it easy to regulate pump speed and grease flow, ensuring a steady, consistent and even flow of grease to the lubricating chamber. This enables better-controlled and faster lubrication of wires.

The wire rope lubricator is supplied with seals in 1mm increments, from 1mm to 50mm (a larger lubricator for wire diameters up to 90mm is available on request).

Optional groove cleaners are also available for removal of old grease, Groove cleaners are made for a specific wire size and construction and remove up to 90% of old grease, dirt and debris. This enables better penetration of the ingoing grease into the wire core, and a better protected wire.

Wire Greasing

Wire Greasing

Mooring Wires

Mooring Wires

Crane Wires

Crane Wires

Cold Climate Greasing

Cold Climate Greasing

Ramp Wires

Ramp Wires