Main applications:

Stainless Steel

Stainless Steel

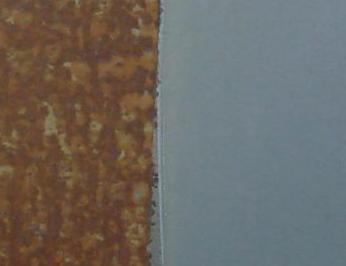

Because of salt exposure and high humidity at sea, stainless steel will only look its best for a limited time. Lower grades of stainless steel are employed by some manufacturers as a cost cutting measure but even "marine grade" (SAE 316) stainless steel, especially on outer decks, will start to corrode within the first few years of exposure. This issue affects couplings, brackets, boxes, signs and railings.

Any grade of stainless steel will resist corrosion better than carbon steel, but if left untreated the rust will start to weaken the stainless steel. At an early stage, there will be visible rust on the once bright, lustrous metal, which will continue to spread on the metal and surrounding areas in the form of rust stains.

Ferryl 401 Anticorrosive Transparent Coating is designed to preserve the original shine of stainless steel. It is a one-component, clear varnish-like product that is applied to the metal before corrosion begins.

Ferryl 401 creates a plastic-like shield on the metal surface with built-in chemical rust inhibitors. The coating provides a barrier between the metal surface and saltwater, preventing the corrosion process. The plastic components in the coating give the coating flexibility, which combined with UV-stabilisers, reduces cracking and ensures longevity of the coating.

On uncoated stainless steel where the corrosion has begun the rust can be removed using Ferryl Ferrycid Rustremover, after which the steel can be coated with Ferryl 401.

Once coated, the stainless steel parts will remain rust-free and maintenance-free for many years.